The Extruder Machine has a Cool starting defensive control device to prevent gear box, motor and screw safety. The extruder machine will start only after achieving the preset temperature to avoid damages to the screw and gear box, motor orchestrated control for pelletizer motor and extruder motor for unchanging element size avoid over feed or under feed to the pelletizer.

APPLICATIONS

Navconic Extruder Machine is suitable for LLDPE, HDPE, MDPE virgin as well as used in recover & compounding persistence. Our Extruder Machine is available in capacity starting from 40 kgs/hr to 300 kgs/hr. We are also manufacturing Extruder machine, recycling plant, recycle plastic, reprocess plastic, plastic extruder machine, plastic making machine, extruder machine manufacturer

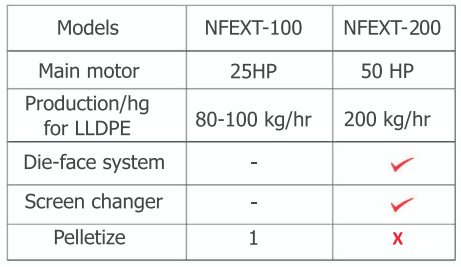

TECHNICAL SPECIFICATIONS

- The machine's screw and drum are designed for dissimilar l/d and density ratio considering density / m.f.i. and melting temperature of the polymer to be treated.

- Meticulousness made special alloy steel screw and drum with wear – resistance, heat treated finishes in up-to-date boiler.

- Well-made helical gear box for care free round the clock working.

- Extruder Machine is made with specially developed heaters for energy competent heating system and temperature control by microprocessor based digital control system.

- Cool starting defensive control device to prevent gear box, motor and screw safety. The extruder machine will start only after achieving the preset temperature to avoid damages to the screw and gear box, motor orchestrated control for pelletizer motor and extruder motor for unchanging element size avoid over feed or under feed to the pelletizer.

- Extruder Machine is made from Stainless Steel material, Palletizer with speed variable drive / DC Motor suitable for different application, cooling tray with stand.

- Air knife for moisture free strands and effectual cooling off the strands and pellets.

- We are providing High efficiency hopper magnet with the machine to detect the metallic inclusion parts from the polymer.

- Feeding hopper display low level indicator. Auto tripping system available in case of excess feeding.